Leachate and wastewater treatment plant of the Mancomunidad del Este CMR in Loeches

PROTECMED has carried out the design, detailed engineering, supply, assembly and start-up of the liquid waste and leachate treatment plant generated in the Waste Management Environmental Complex of the Commonwealth of the East in Loeches. The treatment system consists of a first physical-chemical phase followed by a two-stage concentrative reverse osmosis system with open channel RO modules.

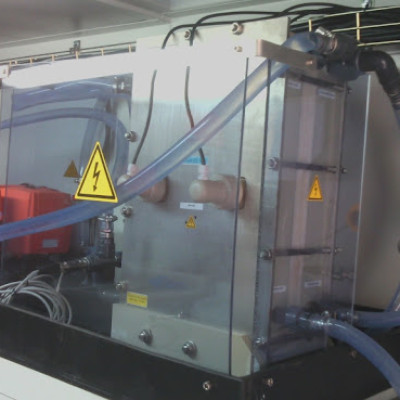

The feed pumping, homogenization and neutralization tank, physical-chemical treatment, DAF dissolved air float, APQ tank of concentrated sulfuric acid, containerized Reverse Osmosis plant and degassing tower have been supplied. Reverse Osmosis features automatic sand filtration, cartridge filtration, high pressure pumps, membrane cleaning system, and two complete leachate and permeate stages.

The treatment plant has a hydraulic capacity of up to 150 m3 / day, which will make it possible to treat all the leachate and other liquid waste generated by the Loeches CMR.

As a manufacturer PROTECMED has used the best materials and the best quality equipment. The electrical panel, the operating logic and all the PLC programming have been designed and implemented by PROTECMED technicians.

The treatment plant built has the following advantages:

- Compact system, built and fully factory tested.

- Since the process of separation of pollutants by reverse osmosis is physical, this plant has great stability and flexibility in the face of variations that may occur in the quality of the leachate and other AARRs to be treated, as long as the requirements are not exceeded. critical limits of the process.

- The use of "open channel" osmosis modules makes it impossible for irreversible fouling to accumulate on the membranes during the process, as long as the system works with the appropriate pressure, pH, performance and chemical cleaning parameters.

- The main operating parameters of the plant are automatically controlled by the PLC: pressure, temperature, pH, conductivity and flow rate. Continuously and also remotely, it is possible at all times to know the situation of the machine and control its operation. It is possible to view on-line the status of the entire system and control parameters, monitor the operation of the plant through historical records, modify the operating instructions when necessary, notify alarms and record data.

- The quality of the permeate, the treated water, will always be excellent, regardless of the load variations that the osmosis modules receive. This treated water can be recovered and reused for various uses within the CMR.